Installation of a retractable door in the wall in 10 steps

Installation of sliding doors step 1. Tools

The list of necessary tools will depend on the scope of necessary works related to the type of sliding door to be installed and the preparation and finishing of the opening for them. In the simplest variant - including wall mounting, a company set - you will need a hammer drill with drill bits for brick and / or concrete, a hacksaw, a tape measure, a spirit level and a set of wrenches and screwdrivers for screwing and adjusting. Screw spacers or properly cut boards will be useful to embed the finished border.

If you use a ready-made cassette, you also need to obtain tools for finishing the plasterboard covering - a putty, a container for gypsum mortar, a sandpaper holder, a brush. If the door opening needs to be adjusted, then masonry tools (trowel, hammer, float) will be useful, and sometimes also an angle grinder with a disc for cutting concrete and / or stone. When making the frame yourself, we will use carpentry tools - a wood saw, angular framing (miter box) and carpentry clamps.

Installation of sliding doors, step 2. Materials

When you buy a company set for sliding doors, you will find in it almost a complete set of the necessary equipment. We will only have to purchase fasteners (wall plugs), mounting foam, glue or silicone. In the case of the cassette, you will need plasterboard and putty to finish them.

When assembling the necessary elements yourself, you should select the appropriate door leaf from the range of non-rebated models intended for tilt assembly with a recessed handle, knob and possibly a hook catch, or order a laminated chipboard or a stile with decorative filling.

We will also purchase a complete guide with trolleys, limiters and handles and a wooden access beam - in the case of mounting the door in the wall version.

As finishing elements, we will use profiles with a suspended masking frame or leave it uncovered if it is mounted with decorative trolleys and handles. When preparing the cassette, you will need rack profiles used in the drywall system and the necessary connecting elements. Fastening to the wall and lintels is ensured by expansion bolts or anchors selected for the base material.

Installation of sliding doors - step 3. Choosing the type of door

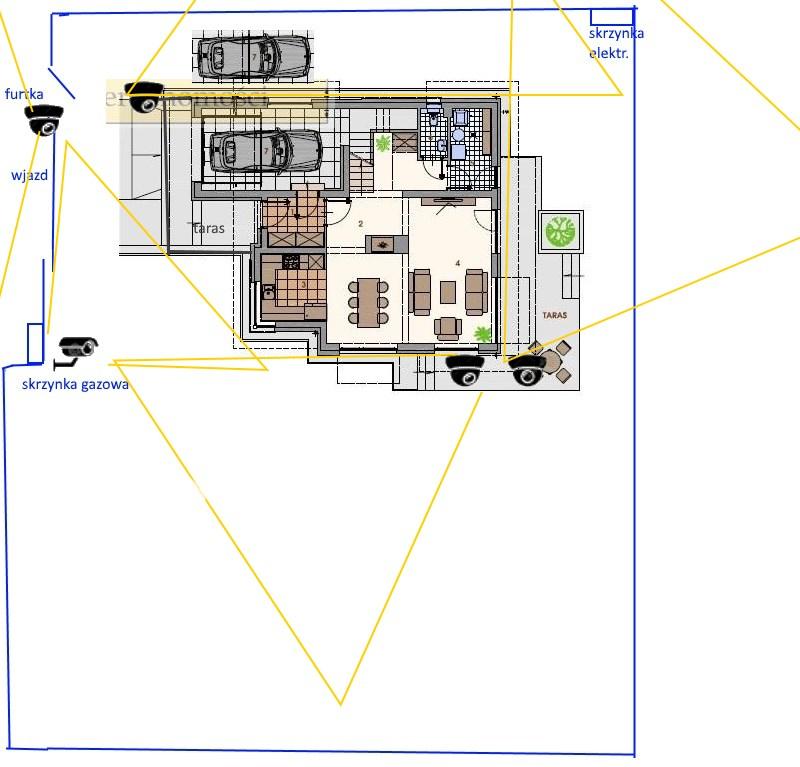

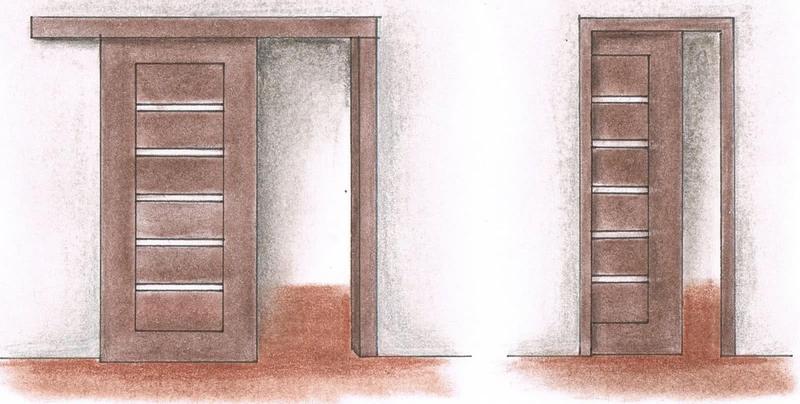

Replacing standard sliding doors is becoming more and more popular, and sometimes even necessary when, for example, slants prevent the full opening of the sash. Sliding doors can move outside the wall or hide in the wall, i.e. in the added cassette. In the opening up to 90 cm wide, a single sliding sash is placed, in the larger ones you will need two.

Installing the leaf that moves along the guide on the top of the wall requires free space on the side of the opening - although the open door will cover a part of the wall, but leaving some space, you can, for example, plan a shelf behind which the leaf will be hidden.

Do you appreciate our advice? You can get the latest every Thursday!A door hidden in the wall is made, for example, when we want to close a wide passage - found in old houses - connecting rooms in the enfilade. Also, if the room is divided with a light partition wall, it is easy to hide the door leaf on one side. When deciding on one of these variants, we have to choose the type of sash, the form of jambs or masking the rail.

Most models of typical non-rebated doors, laminated chipboards and light wings for built-in built-in wardrobes are suitable for sliding installation. The reveal can be finished with matching strips or system-adjustable bands. The most convenient way to use the complete sets for the installation of sliding doors, offered by manufacturers of joinery.

Assembly of the sliding door, step 4. We check the assembly conditions

Before buying materials, we must check the dimensions of the opening and determine the direction of opening the sash. If the opening in the wall was made immediately for such construction, you only need to align the jambs by correcting its width, e.g. with plasterboard strips. If we use standard sashes, we adjust the width of the opening (taking into account the thickness of the finishing bands) so that it is approx. 5 cm smaller than their external dimensions. The height of the door opening should be slightly smaller than that of the leaf mounted outside the wall, and 6-8 cm higher with retractable doors - depending on the size of the guide and rolling carriages.

We also have to check the perpendicularity of the sides of the opening, especially on the access side, and the structure of the lintel. The problem may be the attachment of the guide - both wall-mounted and hidden in the reveal - if there is a steel beam there, which happens in the lintels of old load-bearing walls. Of course, the beam can be drilled, but it will be more difficult and requires the use of a special drill. If we decide to hide the door in the wall, it is necessary to determine how to adjust the thickness of the cassette to the thickness of the wall. Finished cassettes are usually designed for walls 10-12.5 cm thick, which corresponds to a typical construction in a skeleton wall.

In the case of a wider wall, in the door opening, we can create the necessary supporting grating ourselves and cover it with plasterboards. The depth of the cassette should be slightly greater than the door width - additional space is needed for the elements limiting the movement and mounted on the rail.

Mounting the sliding door, step 5. Installing the retractable door cassette

A detailed description of the order of assembly of the finished cassette can be found in the instructions attached to the product. Adjustment may be required by the height of the lintel and the adjustment of the covering to the thickness of the wall. The surface of the cassette can be leveled with the rest of the wall (with differences in their thickness) by gluing plasterboards with two layers or by attaching an additional grate, eg made of wooden slats "thickening" the cassette.

If we decide to build a cassette ourselves, we can use system plasterboard profiles for this purpose. The starting dimensions for selecting the elements of the grate will be the thickness of the leaf and the width of the guide. The standard assumption is 40-45 mm for the finished swing door. The thin, metal frame can be formed from CD ceiling profiles and CU wall profiles. Two rows of the grate, each 28 mm wide, are set up, which, with a 12.5 mm thick board sheathing, gives a total wall thickness of 120-125 mm, which is similar to a standard brick wall. The grate is made of special C and U profiles with a nominal width of 20 mm, which is even smaller.

For larger wall widths, the grating is made of standard CW and UW profiles, 50 mm wide. Such a cassette is 165-170 mm thick, but it can be thickened by arranging any rows of profiles. The construction of the cassette structure begins with attaching the CU profiles to the floor in a symmetrical arrangement with respect to the lintel line, with a width that enables the cassette cover to be flush with the rest of the wall (12.5 mm offset under the board thickness).

In the same spacing, we place the profiles in the lintel. Since they are placed close to its edge, the pins will not be firmly attached when we hit the plaster layer. A more stable connection will be ensured by screwing them to the angles attached to the front of the wall, or to flat bars screwed to the bottom of the lintel. Insert the CW posts into the profiles attached in this way - with the flat side out. Place the posts every 40 cm and screw them to the shelf of the CU profile. Until the sliding leaf is finally seated, at least one side of the cassette is left uncovered in order to be able to adjust the travel stop and the brake.

Mounting the sliding door, step 6. Mounting the support rail

Depending on the way the door works, the rail is placed over the door opening or on the underside of the lintel. When mounting on the wall - the height of the guide is adjusted to the height of the sash, adding the dimensions of the trolleys and running tracks. It is important to maintain the same distance between the track and the floor level along the entire length of the travel.

With an even floor, it is enough to determine the rail mounting height and fix it horizontally using a spirit level. Any unevenness must not exceed 0.5 cm along the entire travel length, as larger ones will force the sash to be raised excessively, creating a gap, and the bottom guide will fall out of the groove. The wall guide is fixed with the angular brackets twisted with the rail and attached to the wall with anchors. The handles are to adhere to the wall. If necessary, pads (metal or plastic) of matching thickness are inserted under the mount.

Due to the weight of the sash and the unfavorable load on this element, we have to choose the fixing pins depending on the wall material. When embedding in a weak substrate (cellular concrete, hollow bricks) or in plasterboard walls, it will be necessary to strengthen the fastening (additional profile in the wall, chemical anchors). The guide for the door hidden in the cassette is attached to the bottom of the lintel, so its height from the floor is to enable the installation of a wing of the selected height, taking into account the dimensions of the suspension.

Sometimes it may be necessary to trim the sash and it is better to do it from the top, because any damage will hide under the mask, and the factory-cut guide groove will not need to be recreated. A separately purchased guide can also be shortened to the desired length.

Installation of sliding doors - step 7. Suspension of the leaf and its adjustment

Suspending the leaf on the guide requires fixing the trolley handles on its upper surface. The handles are screwed with screws at the distances from the edge of the leaf indicated in the instructions. It is necessary to pay attention to the leaf thickness recommended for a given rail and its permissible weight. The handles have oval holes, so they are easy to mount on the stroller slings. After the initial setting, the length of the sling is used to adjust the height above the floor and the parallel position of the sash sides in relation to the jamb. And in a fixed position, we lock in the joint by tightening the locknuts.

Thanks to the sliding stops, we can set the extreme positions of the sash. In the closed position, it must not hit the access beam or the reveal frame, and in the open position, there must be easy access to the handles. Sometimes the guides are equipped with additional elements, such as a silent closing unit, automatic closing, locking in specific positions. If they are mounted in a retractable door, any adjustments must be made before the final plasterboard covering and finishing on both sides of the cassette.

Mounting the sliding door, step 8. Installing the bottom guide

The bottom guide prevents the door leaf from tilting sideways. We mount it to the floor approx. 5 cm from the end of the closed door. It is invisible, as it fits in the thickness of the door leaf, and keeps it in a straight line thanks to the pin entering the groove cut from the bottom of the door. Determining the position of its mounting in the case of a wall-mounted model consists in checking the width of the gap between the closed leaf and the wall plane - it must be the same along the entire height of the door.

As the guide is hidden under the door leaf, its positioning during assembly will facilitate its temporary attachment to a flat object (cardboard, metal plate). After inserting the guide into the guide slot in the wing, we determine the vertical position of the door, and then draw the outline of the auxiliary tile on the floor. After removing the sash, place the template in the marked position and attach it to the floor through the holes in the guide.

In the case of doors hidden in the wall, the guide is placed at the edge of the cassette and in the guide axis, which should correspond to the distance from the sides of the frame. We install it before hanging the sash, which we then slide in and rest on the guide. When thin wings, e.g. made of laminated chipboard, are fitted, the outer guides are also embedded. They are also bolted to the floor near the end of a closed door.

Such leaves require adjusting the spacing of the protrusions to the thickness of the door leaf, which is smoothly or stepwise adjustable, and adjusting to the thickness of the leaf should provide 2 mm of play along the entire travel length.

Installation of a cassette for a door hidden in a plasterboard wall

Installation of the sliding door, step 9. Clamps for the opening

The jambs of wall and hidden doors must be protected against damage to the edges - with the use of system clamps (which are part of a complete system) or made by yourself. You can also omit the decorative finish, leaving the edges evened with plaster. However, it will be necessary to attach an access beam to the wall door, which will allow for their stable and tight closing. We will install the system ties in accordance with the manufacturer's instructions, possibly adjusting the length of the side elements to specific dimensions.

It is also important to maintain the same spacing along the width. When depositing on the foam, appropriate 3 or 4 spacers should be inserted for the time of its hardening. Self-selected framing, e.g. made of wooden angles or paneling, is glued with glue, and the gaps at the contact with the plaster are filled with acrylic mass. As a rule, we also install a guide cover, if we have not used its decorative version.

When mounted on a wall, it is made of a box cover, e.g. made of wainscot panels, hung on hook holders. In the door hidden in a cassette, the visible section of the guide can be easily masked with a plasterboard strip or a decorative panel. We screw them on the underside of the lintel on the angle brackets.

Installation of sliding doors, step 10. Handles and closures

Sliding doors must be equipped with handles on both sides, enabling them to be conveniently opened and closed. A typical solution are recessed handles that do not protrude beyond the plane of the leaf. However, their installation requires a fairly precise milling of the recess.

A door with such a handle is better to buy ready-made. We can easily attach knob handles, which will also be used to unlock the hook catch. When embedding them, it will be necessary to limit the depth of hiding the sash in the cassette or the movement when opening the wall door so that the knob does not hit the edge of the opening. It is necessary to adjust the stop on the guide.

The hook catch will be needed if we want to lock the door with a key, and also install a suitable handle. Then we also have to install the catch plate in the access beam and make a recess for the hook.

Instructions for self-assembly of sliding doors.

Cezary Jankowski photo by opening: Eclisse